OUR SERVICES

From the raw part through semi-finished parts to the finished product

Our highly qualified staff and modern machinery enable us to manufacture the most demanding quality products for you. Our range of services covers all facets of product manufacturing – from design and development in CAD, through production with CNC milling, turning and grinding machines, as well as surface treatment, to the assembly of entire assemblies and devices. All our production parts are subject to strict quality control to ensure that they meet your requirements.

PRODUCTION & MANUFACTURING

Production process

On the basis of your drawing or the CAD data set, we produce the ready-to-install component from the semi-finished product or from a supplied blank.

Our MachineryCNC-Milling

With our modern CNC milling machines we are able to achieve the most precise manufacturing tolerances up to IT6. We use 3-, 4- and 5-axis machines, which allow component dimensions of up to 5000mm

CNC-Turning

Lathes with main and counter spindle, as well as driven tools and an additional Y-axis enable us to achieve manufacturing tolerances up to IT6

Grinding

A wide range of external cylindrical, internal cylindrical and surface grinding enables us to achieve finest manufacturing tolerances up to IT3

Honing & lapping

By honing and lapping we achieve highest surface roughness qualities

Welding

Welding with TIG or MAG/MIG processes, as well as brazing of your components and assemblies can be offered as part of our range of services

Quality control

We are able to carry out extensive quality inspections with a wide range of measuring equipment, such as 3D measuring machines and roughness testing equipment.

DEVELOPMENT & DESIGN

Are you still in the development of your prototype? We support you also in this area!

With our expertise in prototype construction, we provide you with target-oriented support in all steps of your in-house development. We offer you technical and manufacturing support from the design on the CAD model and all necessary production techniques to the optimization towards serial production. Consulting for production optimization is a matter of principle for us in close cooperation with our customers.

Send inquiry

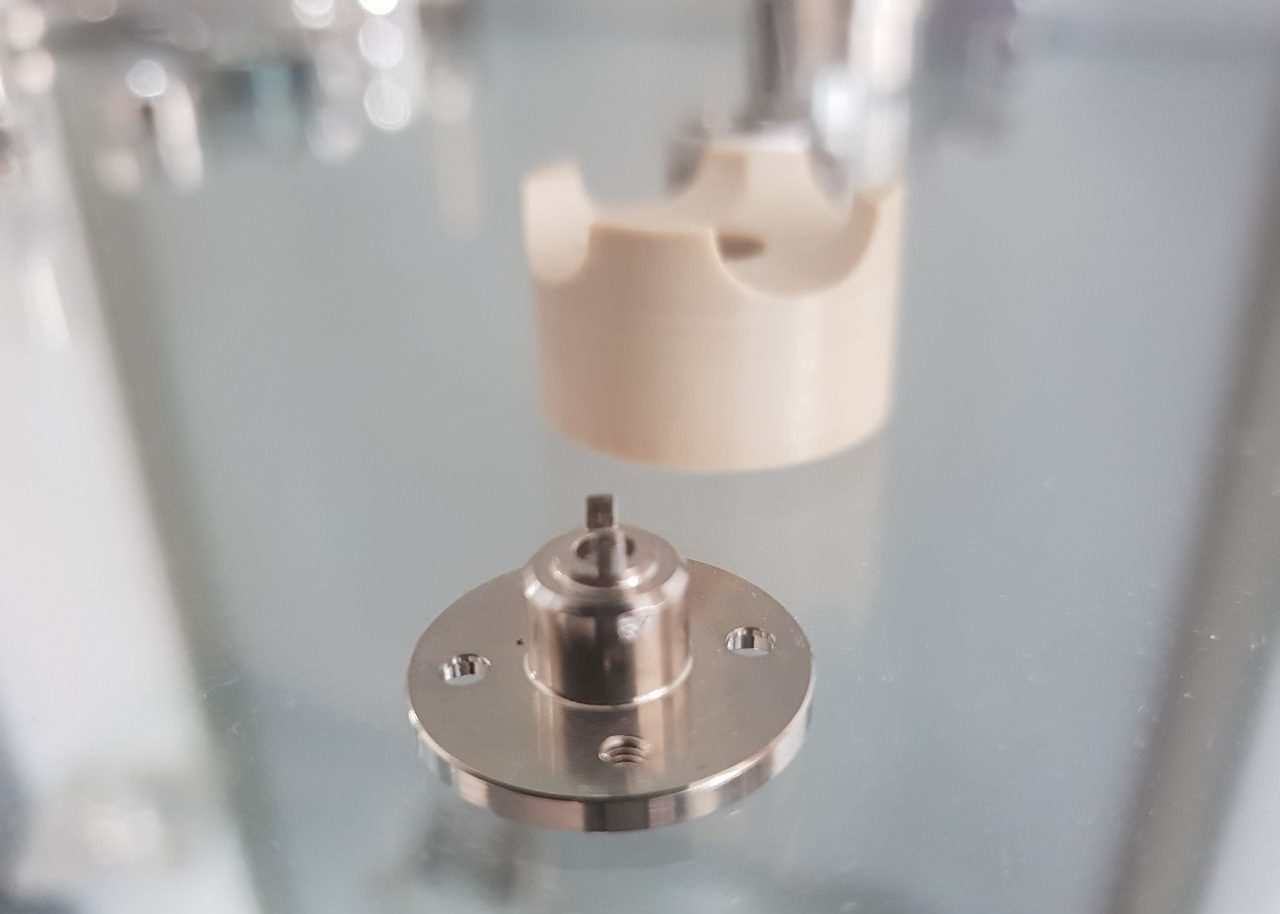

Assembly

Sample and device construction

Your product consists of several mechanical or electronic components that need to be assembled or otherwise joined together? You can also count on us for this. With the procurement and production of all components, as well as the assembly of components or subassemblies, we round off our range of services and can thus deliver a complete and perfectly matched product.

Mechanical subassemblies

We carry out the assembly of smaller components with the utmost care and can thus react to special customer requirements easily and flexibly.

Complete mechanical products

Products with demanding mechanical functionalities require a high degree of coordination in production and assembly. We offer you exceptional quality and customer service for the best possible results.

Mechatronical systems

Thanks to our ESD-protected assembly areas, we can also assemble complete mechatronic systems with finely tuned assemblies and electronic components and deliver them ready for operation.

Design: Kirsten Albrecht – www.kirsten-albrecht.de

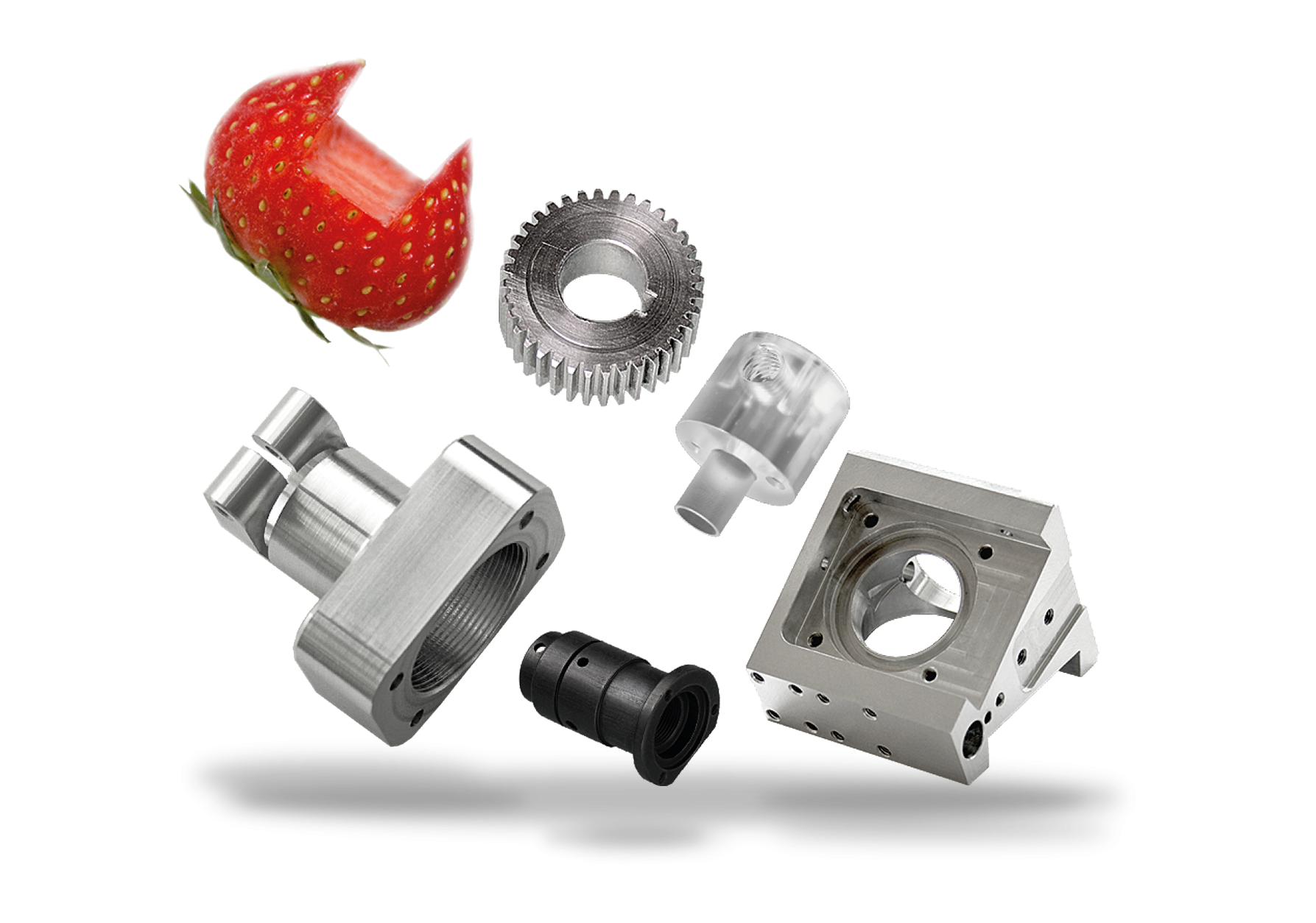

MATERIALS & ADDITIONAL SERVICES

Materials & Surfaces

We machine almost everything – except maybe fruit (at least not yet). Of course we work with all common steels, non-ferrous metals and plastics, as well as titanium and Inconel. In order to provide your product with the necessary surface quality, we also offer a variety of possible surface treatments. For example, you can have your components hardened, nitrided, anodised, polished, trowalised and chrome-plated, as well as nickel-plated or even painted and provided with various other coatings.