radotec – The medium-sized precision engineering company in a valley near Munich

We are a company based in Krailling near Munich, specialising in high quality precision turned and milled parts. As a family-owned company, we have been offering tailor-made production of individual parts, series, assemblies and prototypes for leading companies from a wide range of industries – such as medical technology, aerospace, automotive, electronics and chemicals – for over 70 years of company history.

Our core competencies for your success

The highest level of quality is guaranteed when customer satisfaction has also reached a maximum level. Our precision mechanics company has stood for this principle for over 70 years. Therefore, we attach great importance to the individual coordination with the customer.

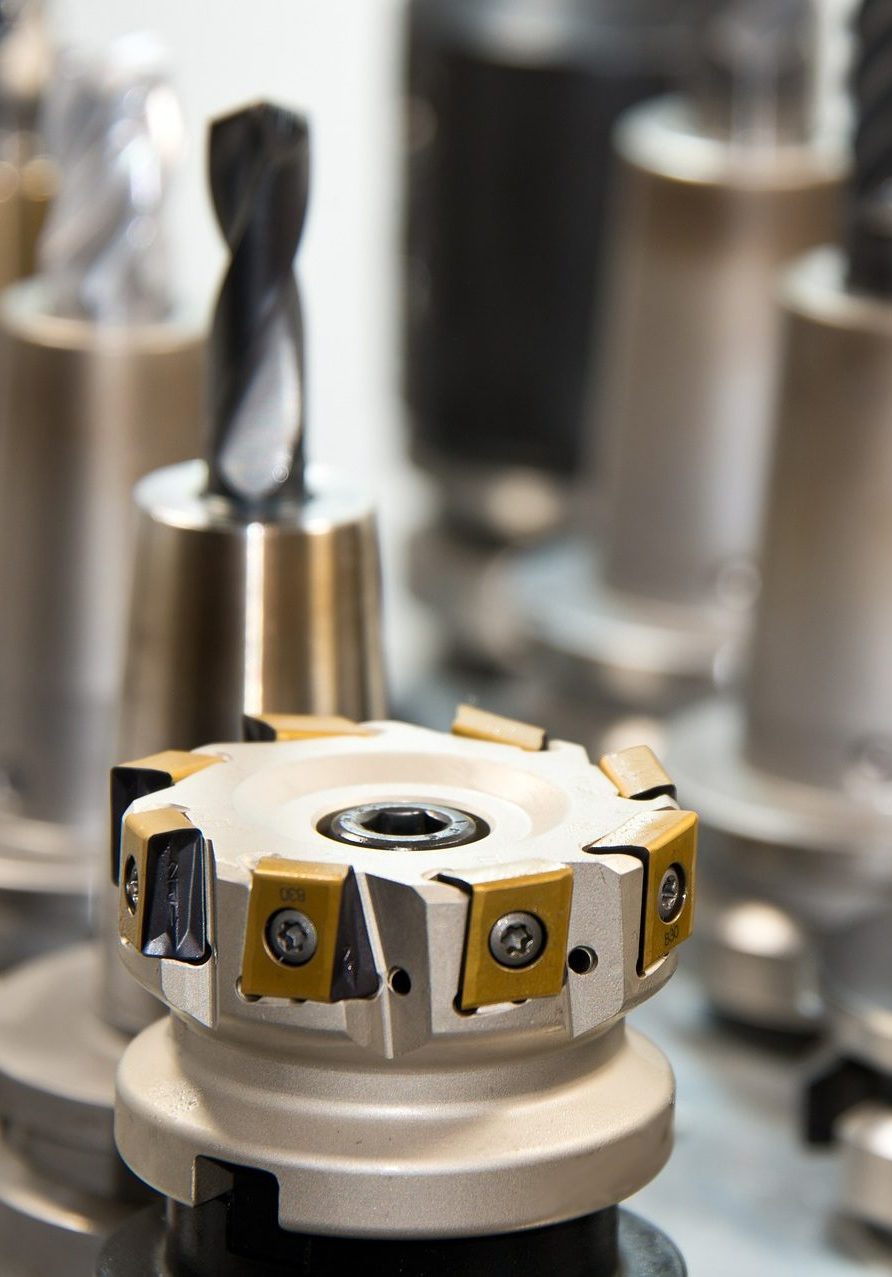

Production & manufacturing

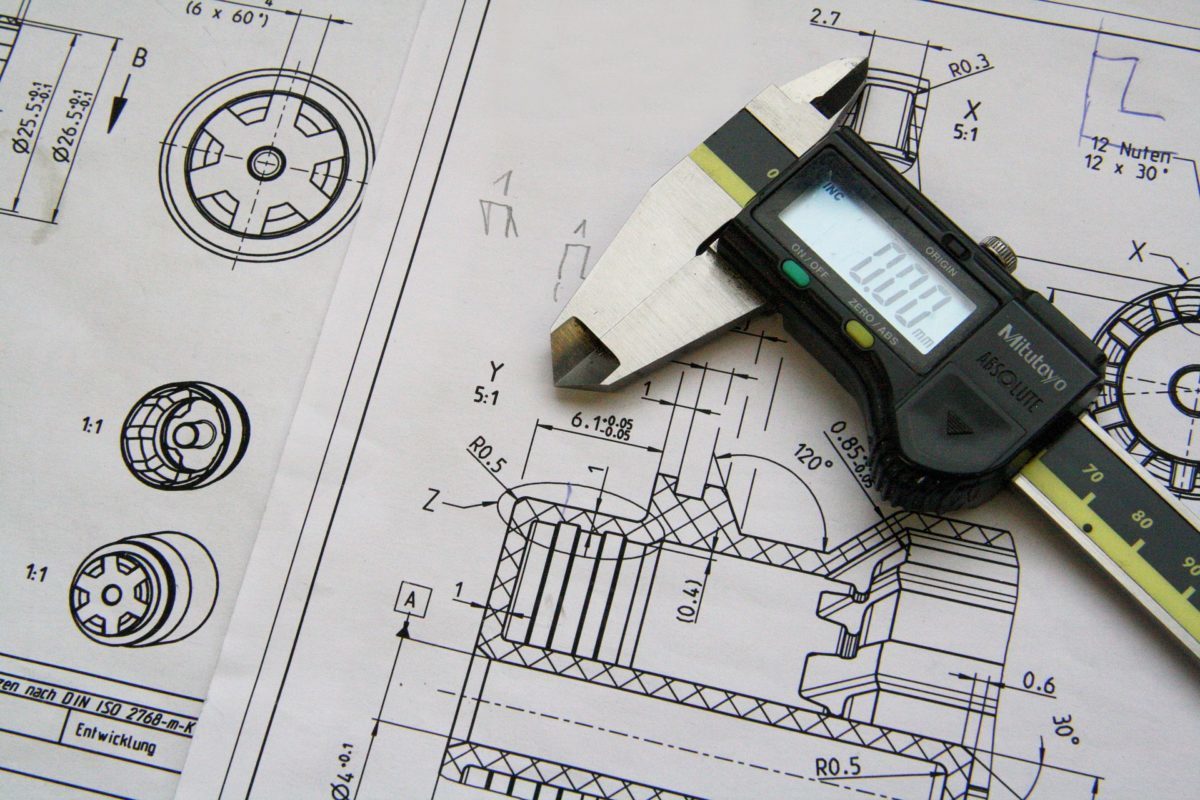

On the basis of your drawing or the CAD data set, we produce the ready-to-install component from the semi-finished product or from a supplied blank. Here we can use our complete service portfolio.

learn more

Design & development

With our expertise in prototype construction, we provide you with target-oriented support in all steps of your in-house development. Right from the first development steps, we offer you professional support for a function and production-optimized design of your product.

learn more

Sample & device assembly

Your product consists of several components that need to be assembled or otherwise joined together? You can also count on us for this. We take over the assembly of components or subassemblies and can therefore deliver the individually manufactured components as a complete functional unit.

learn morePrecision engineering with tradition

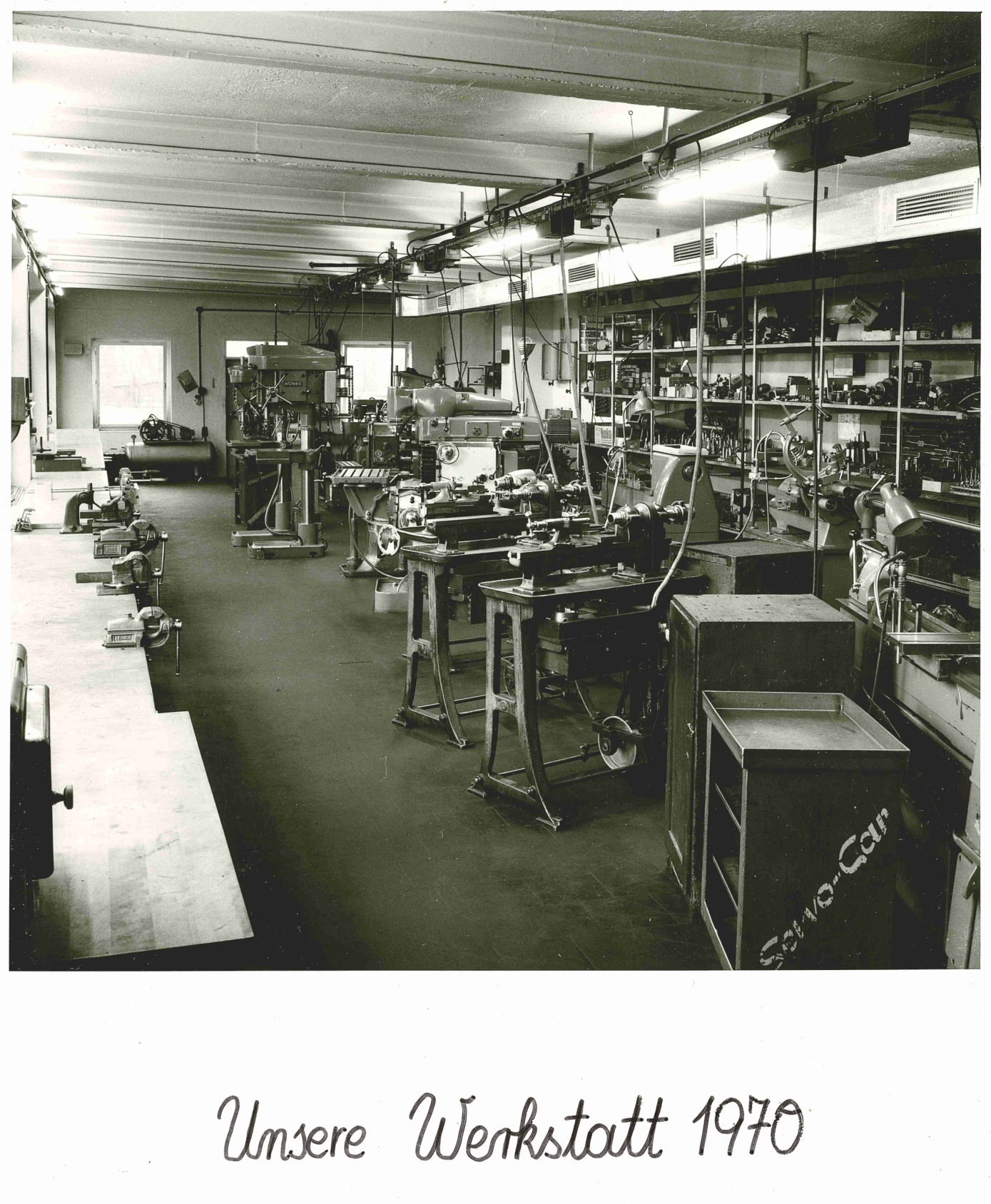

As a family business, we look back on over 70 years of experience and tradition in precision engineering and prototype construction.

1948 – Roots of the company

In 1948, Rudolf Knill founded the company in Gräfelfing and thus laid the foundation for today’s company. What began at that time with the specialisation in locking and security technology, developed continuously into a company that covers the entire range of precision mechanics with professional competence.

2006 – Founding of radotec

After moving to Krailling in the Kraillinger-Innovations-Meile (KIM), the current company headquarters, radotec GmbH & Co. KG continued operations from 2006. With the new owner Dipl.-Ing. Rainer Dollinger and his wife, commercial specialist Ursula Dollinger, the precision engineering company is successfully continued thanks to professional expertise and motivated colleagues.

On principle

FAMILY-RUN BUSINESS

As a family business, we are characterized by our familial and caring working atmosphere. An open ear for the concerns of customers, suppliers and employees is a matter of principle for us. Social responsibility and ethical principles determine our sustainable business decisions and business strategies. That, too, is why we as a company are proud to be considered a safe employer in the region.

CLIENTS

Personal customer care and the highest possible level of customer satisfaction have always guaranteed the success of our precision engineering company. In order to prove this customer orientation and not only to continuously optimize our processes, but also to guarantee product safety, we are of course certified according to ISO 9001 and ISO 13485. Through our fair and trusting cooperation and our proven manufacturing quality, we achieve our high customer satisfaction.

Employees

As a family-owned company that provides training, our employees and trainees are the basis of our company’s success. That is why we attach great importance to a good working atmosphere and a friendly and respectful interaction with each other, which motivates us to achieve top performance. Employees at radotec are not seen as mere clerks, but as colleagues, and this through all levels of the company. As a team we guarantee constant top performance for our customers.

With commitment to a technology-enthusiastic and ecological future

We support young engineering and student teams with developments, production parts and prototypes in various student projects, especially for ecological and sustainable concepts – from electromobility to electric aviation. As a company, we are happy to get involved in these projects in order to make our contribution to an ecological and technology-enthusiastic future.

PROJEKT ELMO

We have already produced individual parts for the student project “Projekt ElMo” of the student group TechFak EcoCar in Erlangen and supported the developments there with our know-how. In this research project at the Friedrich-Alexander-University Erlangen-Nuremberg an electric motorcycle was developed in cooperation with the Fraunhofer IISB, which can also be seen in the video below.

Image- and Video source: TechFak EcoCar Team

TUFAST RACING – FORMULA STUDENT

We also supported the Formula Student Team “Tufast Racingteam” of the TU Munich with production parts for their racing car nb016, which in its year of development took first place in Endurance and Efficiency in the FSG Championship.

Image source: Symbol image

S.I.L.V.E.R.

We were able to support the Silver project, which deals with the development of efficient and autonomous flight models and designs new types of performance components for aviation, in the construction of a hovering frame and first prototypes.

Image source: Projekt Silver

With regard to the environment

Our valley offers everyone at radotec a natural home worth preserving. As a local company, we are therefore also driven by a desire for sustainability. For this reason, we have introduced an environmental management system certified in accordance with DIN EN ISO 14001 and are constantly developing it further. We are committed to new projects with sustainable concepts, continuously implement energy-saving measures and pave the way for sustainable production concepts. From research projects for alternative means of transportation such as electric motorcycle and flying robot concepts to principles of waste avoidance in production – we are actively committed to progress in many areas.